If you’re thinking that the comfortable ride we enjoy today is largely attributed to modern advances in car suspension systems, then you’re absolutely right. But if you’re thinking that your car shocks have a very simple job, you may want to hold that thought since your car’s shock absorbers, or the suspension system in general, have several important roles to play in the optimum performance of your vehicle. Don’t worry, we’ll enlighten you on anything and everything about car suspension systems in this guide.

What is the Function of a Suspension System?

It is quite easy to get an idea of what a car’s suspension system does. From the term ‘suspension’ itself, it is already understood that you are essentially raising something from the ground – to suspend – in an effort to minimize the impact or effects of forces of the ground on this particular something.

For instance, if you lay on your back on the ground, you will definitely feel almost every other vibration from other people walking by. Now try lying on a hammock suspended several feet off the ground and these vibrations disappear. You will surely be swayed by the wind but this is different from ground vibrations. This is, of course, an oversimplification of what car suspension system is. So we’ve outlined a few of the most important functions of a modern car shocks and suspension.

Absorbs vibration, gravitation, and impact forces from the road

We can readily say that the suspension systems of the past were not really that efficient when it comes to absorbing all the different forces emanating from the road’s surface. While people way back then already started using padded cushions to lessen the impact of these forces on their butts, the ride was still far from comfortable. Such systems, thankfully, are a thing of the past. And while there may still be some car models that have suspension systems that are designed like those from the past, many of them provide greater shock and vibration absorption. So while it is not really a perfectly smooth bump-less ride, it is not bumpy either.

Keeps the car’s tyres in contact with the road surface

While it is actually the tyres that are in contact with the road surface, the layout of a vehicle’s axle and wheels is inherently connected to the vehicle’s suspension system. The shocks and vibrations and all other road imperfections that are absorbed by the tyres are also transmitted through the car’s shock absorber mechanism, further dampening the effects of these vibration and shock forces.

Technically, the spring mechanism that is part of modern suspension systems is what pushes the wheels, hence the tyres, against the ground. When your vehicle’s tyres get momentarily airborne perhaps because it hit a big bump, the suspension system will attempt to push the wheels downwards in an effort to reach and reestablish contact with the ground surface. You can easily imagine a car without springs connected to its wheels. Every bump on the road will send the vehicle jumping off the ground. When you make a high-speed turn on a corner, the inside wheels will be lifted off the surface of the road, increasing the risk of flipping over. But if you have a suspension system, then the inside wheels will remain in contact with the ground since the springs on the suspension mechanism will push the wheels towards the ground.

If you take these two functions together, you can see that a car’s suspension can improve overall vehicle safety and performance. By keeping the wheels in contact with the road surface at all times, this helps minimizes rolling and flipping over. It also helps ensure that power is transmitted to the wheels where they are needed most, although this is a function of the vehicle’s transmission.

How Does the Suspension on a Car Work?

To put it simply, a car’s suspension is what separates our behind from the road while also preventing our vehicles from shaking and disintegrating itself into smithereens. The point is quite simple. Even when you have the best engineered road in the world, if you hurl a 2-ton metal at 80 mph you’re bound to get into serious trouble; you or your vehicle. So how do car suspensions really work?

If you look at every car that rolls out of the assembly line, almost every single one comes with independent suspension. This means each of the wheels or the axles are independently suspended so that when one wheel loses contact with the ground, the other 3 wheels are still in communication with the surface.

If you’ve owned a toy car when you were still a child, you’d know this. Since the wheels on these toy cars were not ‘individually’ suspended, when you raise one corner of your toy car, the wheel on the same side of the elevated corner is also raised. Now, if there is independent suspension, then the wheel in this side of the toy car will remain in contact with the surface.

Dependent suspension

This design of suspension system is very simple and as such is preferred by automotive manufacturers and even by DIY enthusiasts who would like to minimize cost while still delivering the basic functions of the mechanism. You can still see this type of setup in modern cars especially in off-road vehicles. But honestly, how many among your office-going friends do you know will gladly take an off-roader to the office on a daily basis?

Anyway, most of the vehicles that still employ the beam axle design have two different axles: live and dead. The live axles come with powered wheels while free-spinning tyres are mounted onto dead axles. Unfortunately, there’s a major issue in such design. Since the tyres will be moving dependent of each other, their focus will be on the maintenance of the same angle relative to each other and not relative to the ground surface. What this simply means is that handling becomes less predictable as you’ve got less traction in your tyres. Just think of that old toy car of yours.

There is another issue inherent in dependent or beam axle systems. This design can greatly contribute to an increase in unsprung weight or weight that simply is not supported by the suspension parts of your car. Technically, this includes the mass of the wheel axles, tyres, wheel hubs, and other components that are not supported by the car’s suspension. High unsprung weight can amplify vibrations or bumps felt on the road since these forces that are supposed to be absorbed by the tyres are generally transmitted into the beam suspension parts. This in turn creates movement in the parts since there is significantly greater mass in beam axles than in independent suspension systems. Additionally, high unsprung weight can also lead to issues of wheel control especially during hard acceleration or even braking.

However, if the differential is attached to the vehicle’s body or frame instead of directly on the axle, then unsprung weight can be reduced. Still, it is no match against independent suspension systems when talking about riding comfort.

Independent suspension

As we have already mentioned above, independent suspension systems are the preferred setup by many of today’s manufacturers. Such a setup allows each wheel to travel independently of each other, up and down with the shock absorber and spring that are bolted to one end of a metal frame. On the other end of this frame is a control arm that connects the suspension to the chassis. Other systems come with a wishbone instead of a control arm which technically attaches the suspension frame at two points. The correct positioning of each car suspension parts in a front wheel independent suspension system is crucial to maintaining full control of the wheels while ensuring consistent wheel alignment. This helps ensure much safer operation of your vehicle.

Independent suspension systems designed for the rear wheels are essentially the same as those found in the front wheels, except that these don’t have to take into consideration steering dynamics. Most all-wheel-drive and rear-wheel-drive vehicles will have their differentials mounted to the suspension frame right in the middle of the wishbones or the control arms. On the other hand, front-wheel-drive vehicles don’t require such complicated arrangement of parts. A simple set of shock absorbers and springs is often sufficient.

How Does the Suspension System Help the Car Stay Connected to the Road?

One of the inherent functions of a car suspension system is to help the car stay connected to the road’s surface. The ability to maintain good traction as well as equal or even weight distribution especially in the face of various forces applied onto the vehicle is a direct measure of a vehicle’s road holding capabilities.

If you want to accelerate smoothly, the rear suspension should prevent the vehicle from shifting its weight towards the rear so you don’t launch into the air like some speedboat on a trial run. The same is true when coming to a complete stop. You would want your suspension system to keep the rear end of the car relatively stable while also preventing your front end from diving straight into the pavement just like those base jumpers preparing to dive head-first into the abyss.

Cornering especially at high speeds also requires a really good suspension system. You can almost imagine what will happen if all the weight of the vehicle will be shifted to only one side during cornering. You’ll have a vehicle that is at the brink of performing a variety of lateral barrel rolls, spins, or somersaults, or however you wish to call it. Body roll, as they call it, inadvertently shifts the traction to one side of the vehicle. The inside tyres thus lose traction and may actually be raised a few inches above the surface of the road. It is the responsibility of the suspension system to keep the inside tyres from flying off the pavement.

The point is that any time your vehicle shifts its weight, half of your wheels will be having the most traction. This is an utter waste of power and gives you inconsistent handling.

Here are some traction problems that are, more often than not, attributed to issues in the arrangement of a car’s suspension parts.

Oversteer

If you love drifting, then oversteer is not a problem for you. You clearly would want your vehicle’s tail section to be somewhat spinning out of control such that you are unusually turning in deep on the inside. But on ordinary days, oversteer is never a good thing since it increases the risk of having the car spin helplessly out of control. This happens because the rear wheels have lost traction, sending the tail of the car forward. Positioning the rear wheels at a certain angle where they don’t allow for optimum contact with the road can also cause oversteer.

Understeer

If the problem with oversteer is that your tail-end actually wants to move in front of your vehicle, the opposite is true with understeer. You would want to turn your vehicle in either direction yet your front wheels have lost grip of the ground surface, sending your vehicle way outside the turn. In other words, you overshoot the corner. But there is actually a more sinister implication of understeer. Compared to oversteer where the issue is with the rear wheels losing traction, the problem with understeer is that it may also signal the loss of traction of the front wheels. And since many of today’s cars come in front-wheel-drive configurations, this can have significant implications to vehicle safety.

Bump steer

This is one of the weirdest experiences you can ever have behind the wheel. Imagine that you are driving when you hit a small bump. This turns your car to the right or left even without you turning the steering wheel. This is often an indication of a suspension system that is poorly aligned. What happens is that the poor alignment causes the wheels to be oriented at a certain angle that a small bump can make them deviate from their intended path.

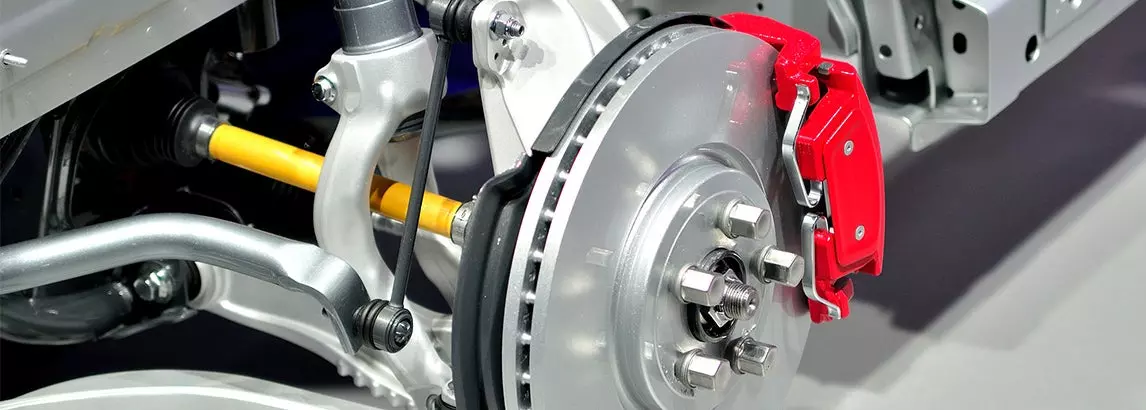

What are the Parts of a Car Suspension?

If you look at the basic construction of a modern car suspension, there are only two principal components or parts. These are the springs and dampening mechanisms. Of course, there may be other parts such as bushings, suspension strut, and others. Here we’ll take a look at the two basic parts of a car suspension.

Spring

This part of the car suspension system is what gives your car the ability to compensate for any irregularity on the surface of the road. It also serves to support any additional weight on the vehicle without excessive sagging. The spring is also that part of the suspension that keeps it at a predetermined height.

There are 3 types of springs currently used in vehicle suspension systems today.

- Coil springs – These are just like the ordinary coil spring that you may have inside your retractable ball pen, although larger and made of exceptionally heavy duty torsion bar. This torsion bar is actually coiled around an axis, hence the name. This type of spring compresses and expands to help absorb the wheel’s motion. Look at the suspension of any car you see today and chances are it will have coil springs in its system. It’s that common.

- Leaf springs – These are perhaps the oldest suspension systems ever designed. The good thing is that they are so simple and very easy to assemble. Don’t believe us? Try looking at the pictures of 18thcentury horse-drawn carriages and you’ll see several layers of metal that are bound together forming a single spring unit. These were the norm until 1985. However, these are still used especially on heavy duty vehicles and trucks.

- Torsion bars – When we talk about torsion bars, it is inevitable that we also think about the unique characteristic of certain objects to twist. It is this twisting ability of an object that gives it a spring-like ability, similar to a coil spring. The object in this case is a steel bar, one end of which is connected or mounted to the frame of the vehicle while the other end is connected to the wishbone. The wishbone serves as a lever. If you hit a bump, the upward movement of the wheel is transmitted to the wishbone which also moves the torsion bar. This twists the torsion bar along its axis, giving it its spring action. European automotive manufacturers as well as Chrysler and Packard in the US used this system in the 50s and 60s.

Air springs

There is another type of spring mechanism that relies on the power delivered y an air compressor. Known as air spring suspension, this is mostly found in trucks and buses as well as luxury passenger cars because of the smoothness of its operation as well as consistently good ride quality. Air springs used the compressive abilities of air in absorbing vibrations and shocks. Today, electronically controlled air suspension systems come with self-leveling functionality as well as raising and lowering modes.

Dampers

While a spring can help absorb the energy off bumps on the road, without a dampening mechanism to help control or dissipate this up and down energy, you will be left with a vehicle that will continue to ‘bounce’ with each bump until such time that the energy has fully dissipated. Try pressing on an ordinary spring and it will continue to bounce several times before it comes to a complete stop. This continuous bouncing action of the spring must be controlled. And this is the primary purpose of a shock absorber, suspension strut, and anti-sway bar.

Shock absorber

In general, a shock absorber is a device that slows down the springing action of the suspension springs while also reducing the magnitude of vibrations. What it does is that it converts this kinetic energy into thermal energy where it can be dissipated with the help of hydraulic fluid.

It is best to view a shock absorber as an oil pump that is located between the wheels and the frame of your car. The upper mount of the shock absorber is connected to a piston rod. The piston rod, in turn, connects to a piston that sits in a hydraulic fluid-filled tube. An inner tube serves as the pressure chamber while the outer tube serves as the reservoir for excess hydraulic fluid.

When you hit a bump, the wheel transfers the energy to the springs which, in turn, transmit the energy to the upper mount, the piston rod, and down the piston. Small holes are located on the surface of the piston, allowing hydraulic fluid to leak through with each movement of the piston inside the pressure tube. Because the tiny holes only allow small amounts of hydraulic fluid to pass through, this slows down the general movement of the piston. As a result, the spring movement also slows down.

It should be fairly obvious that there are two cycles in this operation of the shock absorber. First is the compression which refers to the downward movement of the piston which ultimately compresses the hydraulic fluid below the piston. The second part is the extension cycle which refers to the upward movement of the piston, compressing the hydraulic fluid above the piston. Technically, the compression cycle helps control unsprung weight while the extension cycle controls sprung weight.

There is another characteristic that all types of shock absorbers have – they are velocity-sensitive. As you increase the movement of the suspension, the greater the resistance that the shock absorber provides. This allows shock absorbers to seamlessly adjust to prevailing road conditions and help control any and all of the unnecessary and unwanted motions that can transpire in a moving car. This can include sway, acceleration squat, bounce, and brake dive.

Suspension struts

There is another dampening mechanism that typically works like a shock absorber. This is the suspension strut or simply strut. A suspension strut is actually a shock absorber that is already mounted inside a coil spring, essentially two suspension components in one. This type of dampening structure helps soften the impact of spring forces on the vehicle while also providing structural support for the car’s suspension system. You should recall that shock absorbers don’t support the weight of the vehicle; a suspension strut does.

Anti-sway bars

While not necessarily an integral part of a vehicle suspension system, anti-sway bars or anti-roll bars can, nevertheless provide additional stability for any moving vehicle. Anti-sway bars are metal rods that join the opposing suspension systems on the same axle and are often used in tandem with suspension struts or shock absorbers. When there is movement in the suspension of one wheel, this movement is transferred by the anti-sway bar to the other wheel to create a more even or more level ride. This also helps reduce the swaying tendency of the vehicle especially when turning.

Types of Suspension

Cars typically have different suspension systems for the front and rear axles with each axle providing mounting for two wheels on opposite ends. The type of suspension on any given car is thus determined by the arrangement of the axle; whether it allows for the independent movement of the individual wheels or binds the wheels to the axle. In the former setup, we’re essentially talking about independent suspension systems while the latter refers to dependent mechanisms. Here’s a rundown of the different types of suspension for both the front and rear axles.

Dependent front suspension

We have already described this in our discussion on how suspension systems work. To review, just imagine a rigid bar that connects to the front wheels and typically supported by shock absorbers and leaf springs. This type is common in trucks and hasn’t really been seen any more in mainstream cars. There are 3 reasons why some people hate this kind of arrangement. First, it’s more prone to swaying by virtue of amplification of inertia on one wheel to the other. Second, it increases unsprung weight. Third, it is difficult to adjust the wheel alignment because of the rigid axle.

Independent front suspension

As you may have already guessed, this type of front suspension allows the wheels to move independent of each other, except when they are joined by an anti-sway bar. There are several subtypes of this car suspension system. These include the following.

MacPherson suspension strut

This is the most widely used front suspension system today, but most especially by European brands. It is best described as a shock absorber built inside a coil spring to function as a single cohesive unit. It is more specific for front wheel drive cars.

Double wishbone

This is also known as A-arm suspension because of its unique A-shaped design. It’s called double wishbone because there are two wishbones that connect to the wheel. Each wishbone comes with two mounting positions, one at the wheel and another at the vehicle’s frame. The system also features a coil spring and shock absorber. These are typically used in larger cars and sedans because of the way they help minimize sway while allowing for greater consistency in the steering feel.

There are several types of double wishbone configurations. We already described the Coil Spring Type 1 design above. The Coil Spring Type 2 differs in the placement of the coil spring and shock absorber combination. Instead of this located between the two A-arms, it is positioned just above the upper A-arm. It really is not a very popular configuration since shock and spring combination essentially eats up precious vertical space. The latest double wishbone configuration, typically seen in the A4 and A8 of Audi, is the multi-link suspension. The only difference here is in the way the A-arm is broken down into component sub-arms, generally featuring complex pivot systems. Many say this allows for better road-holding abilities because the multiple joints can be adjusted in infinite configurations for best riding comfort.

Trailing arm suspension

You can think of this as something similar to a double wishbone except that you have especially shaped suspension arms that are connected to the chassis. These arms move parallel to the chassis. It’s an old system. And you can perhaps appreciate this more on a VW Beetle.

Twin I-beam suspension

This front suspension system is seen almost exclusively on the F-series trucks of Ford. It combines solid beam axle with trailing arm suspension. The beam axle is split in two, eliminating the issues seen in dependent front suspension systems.

Moulton rubber suspension

If you have the 1959 Mini, then you’d know what the Moulton rubber suspension looks like. If not, then a mountain bike or racing bike with rubber suspension systems will give you an idea of how the system operates. Basically, the Moulton design replaces the coil spring and shock absorber configuration with a solid mass of rubber.

Transverse leaf spring suspension

Most car enthusiasts find this system odd since it integrates leaf spring with independent double wishbone mechanism instead of the usual coil spring. A leaf spring is positioned across the entire width of the vehicle and connected to the lower A-arms of the double wishbone on both sides. The center of the leaf spring is mounted to the subframe of the vehicle. Take a look at a Chevy Corvette and you’ll get the picture.

Dependent rear suspension

Rear suspension systems have greater latitude in their designs since they don’t actually take into account the steering mechanism. As such, it is quite common to see many cars use dependent systems for the rear axle. Here are some of them.

Solid axle

This has got to be one of the simplest and easiest to set up. You have either leaf spring or coil spring mounted on both ends of the drive axle. The leaf springs and shock absorber mounts are connected directly to the car’s chassis. It may not look elegant but it sure is simple and cheap. If a coil spring is used instead of the leaf spring, control arms are required to provide lateral support.

Beam axle

This type of dependent rear suspension is generally found in cars with front wheel drive systems since the drive axle is located up front. One of the distinguishing features of the beam axle rear suspension is the presence of a panhard rod or track bar. This is a piece of metal that runs diagonally from one end of the beam to a point in the opposite spring mount or opposite control arm.

4-Bar

This suspension system can actually be used on both front- and rear-wheel drive vehicles. It comes in triangulated and parallel configurations. It is the favorite system used by street rodders and even those that ride classic hot rods.

De Dion suspension

This is a rather odd combination of a trailing arm fully independent suspension and a solid beam live axle suspension. While it is weird, it does offer a few advantages such as greater traction and reduced unsprung weight. Unfortunately, it is also weighed down by a host of disadvantages like requiring two CV joints for each axle which adds weight and complexity. The brakes are also mounted inboard which requires the dismantling of the entire suspension system should you decide to change your brake disc.

Independent rear suspension

The same independent front suspension systems can also be used in the rear to provide for a vehicle that truly deserves the badge of having 4-wheel independent suspension.

How Much Does it Cost to Replace a Car’s Suspension?

If you really have to replace your car’s suspension system, you’re actually looking at a hefty bill of up to $5,000, often depending on the type of suspension that your vehicle currently has. If you only need to replace a shock absorber and you think you can do it yourself, then getting a $200 shock absorber should be enough. The thing is that the overall cost will depend on the extent of the damage or the kind of repair that needs to be performed, the make and model of your car, and your very own DIY repair capabilities.

How Long Do Shocks and Struts Last on a Car?

Suspension struts, springs, and shocks are typically engineered to last long. Under normal driving conditions with very minimal potholes, bumps, and other road surface problems, struts and shocks can actually last up to 10 years. However, if you’re taking your car on a daily grind literally, you’ll learn that this 10-year period is usually shorter. Generally, most car manufacturers recommend changing the shock absorber every 40,000 or 50,000 miles. However, a better recommendation is to have the suspension system inspected at 40,000 miles and then annually thereafter.

Why are My Shocks Squeaking?

A squeaky suspension can put you in an embarrassing situation. The good news is that squeaking noise coming from your suspension can be due to issues in the bushings. It is possible that there is a tear in the rubber or even the bushing has already worn out completely. Sometimes, it is also possible that the squeaking sound actually originated from inside the metal sleeve located within the bushing itself. It is also possible that the squeaking sound comes from a damaged rubber boot covering a ball joint or a worn or torn rubber mount. Whatever the case it is imperative that you have it checked immediately to identify the exact cause of the squeaking and for the appropriate management to be carried out immediately.

How Do I Maintain My Suspension?

Maintaining the integrity of your car’s suspension system is tantamount to ensuring a safer drive every time you take your vehicle on the road. Here are some things you can do to maintain the optimum functioning of your suspension.

- Perform a thorough inspection of all the different parts of your suspension system. This is best done after every oil change.

- Inspect the rubber bushings on the track bars, control arms, strut rods, sway bars, and many more.

- Check the different suspension parts for visible signs of cracking, swelling, oil contamination, or even if any of them are missing.

- Clean any debris or oil contamination on any rubber bushing. Oil leaks should be repaired immediately.

- Check the ball joints especially the rubber boots, stabilizer link pins, and tie rod ends.

- If there are grease fittings on your vehicle, make sure to have them refilled with grease with every oil change.

- Check the struts and shocks especially for oil leaks. If you notice these suspension parts to be wet, it usually is an indication that they need to be replaced.

- Perform a bounce test on the suspension. A good suspension system will bounce at most twice. Anything more than that and the shocks or struts already need to be replaced as this is a sign they are worn out already.

New Technology for Suspension

Automotive engineers continue to push the science of vehicle suspension systems. In this section, we’ll try to get a glimpse at two of the up-and-coming suspension technologies.

Magneto-rheological fluid dampers or Ferrofluid systems

In 2006, Audi introduced the TT and with it a revolutionary new suspension technology that works on magnetic fluid known as magneto-rheological fluid. The system boasts of a continuously adaptive mechanism, fully capable of making adjustments depending on gear changes and road surface conditions all within milliseconds. Instead of conventional hydraulic fluid in the shock absorber of the TT, synthetic hydrocarbon oil is mixed with subminiature magnetic particles. The application of voltage to the damper piston coil creates an electromagnetic field. This changes the alignment of the magnetic particles in the oil. Squeezing the oil through the flow channels lines up the magnetic particles, basically ‘stiffening’ the oil. This results in a stiffer suspension.

Linear electromagnetic suspension

Invented by Bose, this digital suspension system replaces the conventional dampers and springs with a power amplifier and a single linear electromagnetic motor. Electromagnetism powers the motor which extends or retracts at amazing speeds to create seamless motion between the car’s body and the wheel.

Your car’s suspension doesn’t only guarantee a more comfortable ride. It also helps ensure that you stay safe while driving regardless of the road conditions.

Sources:

- How Car Suspensions Work – howstuffworks

- How car suspension works – How a Car Works