“Twin-turbo” and “bi-turbo” mean the same thing, some automakers just think one sounds cooler than the other. Parallel and sequential turbos, however, are different. We’re about to get into that and a bit more – welcome to my explanation of how twin-turbos work!

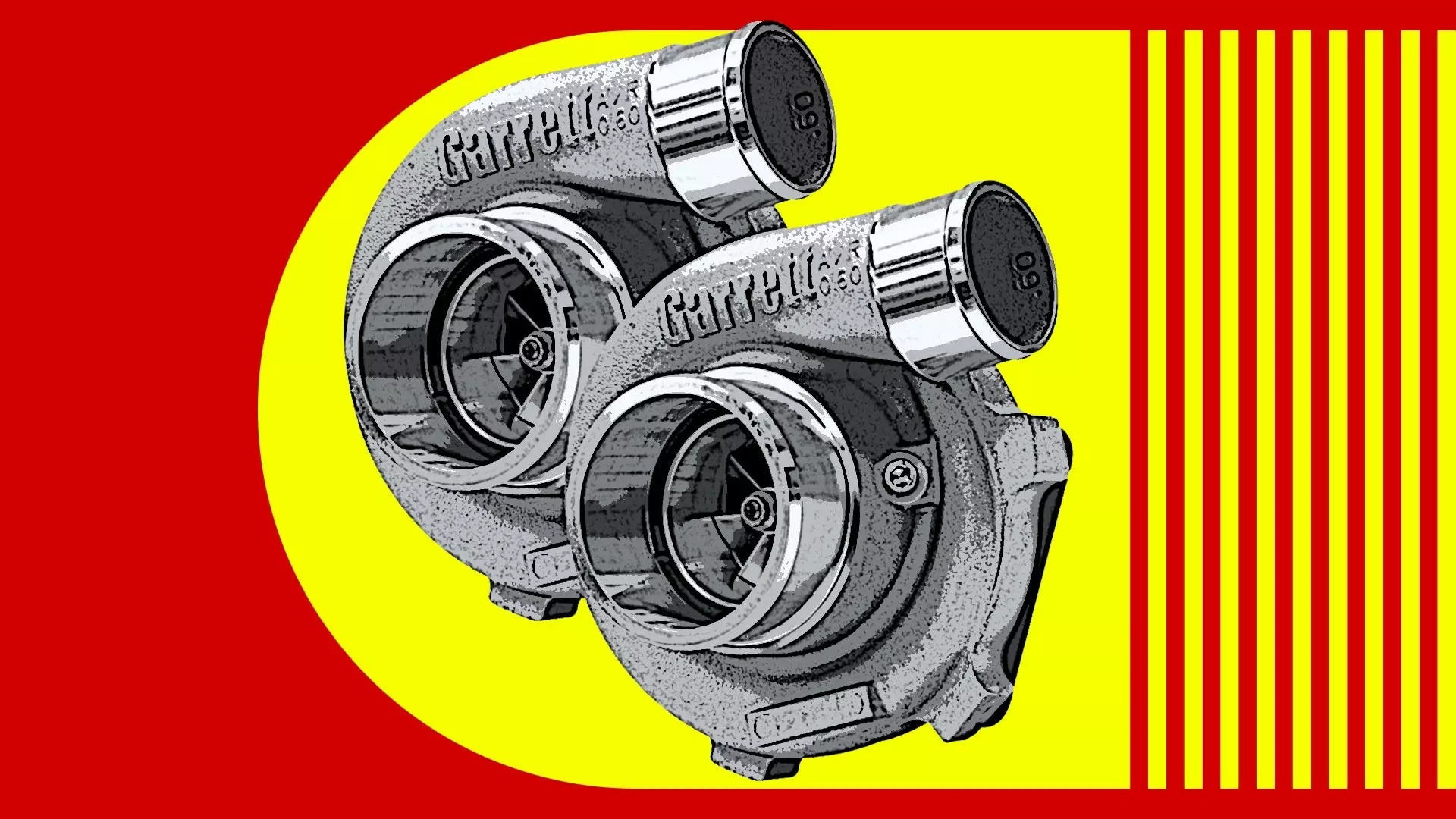

Modern cars use things called turbochargers to convert exhaust heat into kinetic (moving) energy by way of a turbine that spins at very high speed. That turbine is connected by a shaft to a compressor wheel that forces the intake air much more ferociously into the engine. It’s a mouthful right? Some cars have two of those, and they use them in a variety of different ways.

The newest turbo technology has made the twin-turbo functionally obsolete. New turbochargers are so efficient that smaller turbos can do the work of older bigger turbos, without any penalty to performance. To put it simply, this is because the entire function of a turbo is to use aerodynamics on a micro level. Those small turbine and compressor wheels, usually no bigger than 70mm, catch air and move air respectively.

Technically speaking, the turbo doesn’t compress air at all. Boost, psi, all that stuff comes from the air being physically forced to go into the engine, creating a backlog, or a kind of backpressure. Turbos are weird, because you can make more power with less boost on a bigger turbo. Why? Because a bigger turbo can move air more efficiently. For every psi of boost you make, you make more heat, because compressing air heats it up rapidly. More boost isn’t always good.

The tradeoff with a larger turbocharger is that the airflow from the exhaust required to spin the turbo gets higher and higher. There will be a point where the turbo is oversized for the engine, and the engine can’t move enough air on its own to spin the turbo. Most manufacturers aim for a goldilocks zone: nice mid-range punch.

Another fun thing to consider is turbo size affects your power band. An undersized turbo for an engine will make it efficient and punchy in low to mid-rpm. An oversized turbo will make the car sluggish at the bottom, raise the boost threshold, and potentially be laggy, even if it makes excellent high-RPM power.

The more air you can catch and release, in the least turbulent (or sometimes most beneficially turbulent) way, is the big secret of turbo efficiency. Back in the day, before every manufacturer on Earth made a mass-produced turbo engine, the technology was young and inefficient, requiring big band-aids to make work in performance applications. Enter twin-turbochargers.

Bi-turbo, twin-turbo, parallel twin-turbo, or sequential twin-turbo; they all mean the same thing. There are two turbos hanging off of your exhaust manifold. Bi-turbo and twin-turbo is just nomenclature, no functional differences exist between the two.

It gets interesting when we start talking about parallel twin-turbos or sequential twin-turbos. Parallel twin-turbo means that there are two identical turbochargers feeding air and functioning as one, to achieve more power and efficiency than a single larger turbocharger. The turbos ingest air separately, and do not feed each other, and they also receive separate exhaust gases, which is what makes them truly parallel twin-turbos.

An old Supra site actually has a great writeup of various twin-turbo setups that can be used with the venerable Toyota 2JZ, and though the resolution on its illustrations are a little dated the information is timeless and nicely organized.

Sequential twin-turbo means that there are two slightly different turbochargers working together to achieve a very wide power band; to make the engine responsive and usable at low speed, but have the high-speed kick of a larger turbo. Like discussed earlier, a smaller turbo works better at lower RPM, and a larger turbo works better at higher RPM. These turbos also ingest air separately, and do not feed each other, but they share a charge air system. That basically means that they feed pressurized air to the same pipes. The most important distinction is that sequential twin-turbos share the same exhaust gases, and they pass through both turbos on their way to making boost.

It may seem a little hairbrained, but sequential twin-turbos in fact work that way. The FD Mazda RX-7 used a sequential turbo setup that switches around at 5,000 RPM, making for two very distinct powerbands. The A80 Toyota Supra used a sequential setup as well, with a smoother switchover.

The methods to achieve the switchover vary greatly, with Toyota using physical flaps to force more air into the primary (small) turbo, and opening the flaps above 4,000 RPM for the secondary (big) turbo. Mazda used a nutty vacuum system to carefully measure engine load to determine switchover conditions, with a strange-looking siamese exhaust flange and turbos. Seriously, this tech is just ridiculous.

Most modern twin-turbo cars are much, much simpler parallel twin-turbo cars. No crazy switchover, or routing. It’s just two turbos working to make more airflow. Most cars on sale today with twin-turbos are parallel V or flat-engined cars, like the Porsche 911 Carrera. The reason for this is the location of the exhaust manifolds on cars with two cylinder banks make a single turbo impractical to route.

The Mercedes-AMG C63 is a parallel twin-turbo (Mercedes likes the “bi-turbo” term) and has the extra fun-factor of having a hot-V setup. The only old-fashioned twin-turbo setup left is the modern BMW M3 and M2 with the S55 inline-six using parallel twin turbos, a carryover from the old N54. Otherwise, twin-turbo has lost its shine for most, it’s largely a relic of old tech.

There’s a reason a lot of tuners go for aftermarket, large single-turbo setups for cars that came stock with two. Single turbos are smaller than twins, simpler, and can make a lot more power. Twin-turbos aren’t cool anymore. Single turbos are where it’s at.