What is a Flexplate?

Situated between the engine of a motor vehicle, and the gearbox and transmission mechanism, is a clever and essential device that has been fitted to engines of all shapes and sizes since the early days of steam locomotion up to high performance vehicles of the present day. That device is known as a “flywheel” and its somewhat more recent counterpart, which is fitted to engines within vehicles with an automatic transmission, is known as a “flexplate.”

Their roles in the task of driving a motor vehicle forwards, (or backwards for that matter), are virtually identical but it is the specific function of the flexi plate that we are discussing in this article.

Flexplate: What Does it Do? – Back to Basics

The basic principle behind flexplates, and their manual transmission counterparts, flywheels, is to store the energy that is generated by the engine until it is needed and to deliver it in a smooth and even way via the vehicle transmission system, (gearbox) to where it is needed, which is ultimately in the wheels of an automobile, in order to propel the vehicle along.

Internal combustion engines are very powerful but the power that an engine generates is not completely smooth. This is because the firing process comprises of several different actions that, despite happening very quickly, do not happen simultaneously. The power generated by the engine therefore is not smooth but it needs to be so because if it wasn’t the “ride” of the vehicle would be rough and uneven – quite unpleasant for an automobile.

The flexplate effectively captures the energy that is created by the engine and stores it in its large mass by spinning at a speed that, although it is not required all the time, is smooth and even.

The energy held in the flexplate/flywheel is transferred to the gearbox and transmission by means of a system called a torque converter which broadly is the equivalent of a clutch on a manual transmission vehicle.

The role of the torque converter is to replace the clutch on a manual transmission vehicle. In this case, the flexplate would be mounted to the crankshaft of the engine in order to transfer the output (energy) from the engine to the torque converter. The configuration would be for the torque converter to be located between the flexplate and the automatic gearbox unit.

Flexplate vs Flywheel – Some Important differences

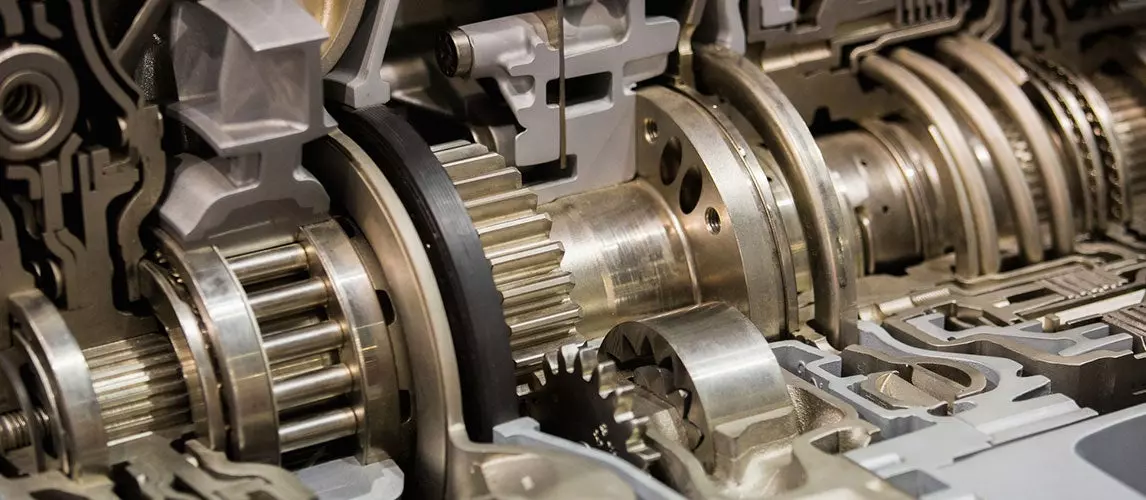

The design of a flexplate is somewhat different to that of a flywheel although they are in essence the same thing – a large wheel that spins at high speed to even out and store energy that is generated by the motor.

Whereas a flywheel is a heavy wheel, a flexplate is usually a somewhat lighter and thinner stamped steel disc fitted with a ring gear welded that couples the torque converter to the engine’s crankshaft. The reason that flexplates are generally much thinner and lighter than a flywheel is due to the fact that the clutch surface that would be found on a conventional flywheel is not required for an automatic transmission as there is no clutch involved.

The flexplate will normally have a variety of holes drilled into its surface which perform various tasks. Some of these holes are to facilitate mounting the flexplate to the crankshaft whereas the others are for torque converter settings and weight balancing – very important for a spinning object in order to avoid bumps and unevenness. Because of the balancing aspect of the flexplate it is important that, when removed for servicing, the flexplate must be replaced in exactly the same position.

What is the “Flex” in Flexplate?

The inclusion of the term “flex” in the name flexplate implies some kind of flexibility and this is another important aspect of a flexplate that differs from that of a flywheel, which is rigid.

The flexplate is made from a sheet of fairly thin stamped steel whereas the flywheel is heavier and solid. The flexibility of the flexplate enables it to adjust to slight misalignments between the engine and the transmission without causing it to crack or otherwise damage the parts involved. A flywheel doesn’t need this amount of flexibility since it is decoupled from the engine by the clutch when the driver changes gear.

Just to put this “flexibility” into context it should be remembered that you cannot manually flex a flexplate – this will normally only occur when the considerable forces of a powerful engine causes the flexplate to spin at high speeds and the torque convertor comes into play in order to change the gear in the automatic gearbox.

Bad Flexplate Indications

How can you tell if something is not right with your flexplate or transmission system?

There are a few indicators that the layman can use in order to determine whether the flexplate has developed a fault or become damaged.

Firstly, when starting the engine, pay attention to the noise made by the starter motor when it spins and engages with the flexplate, or with the torque converter if the vehicle is not fitted with a toothed flex plate. If the starter makes a whining noise while spinning that can indicate a flexplate problem.

Also listen for any rhythmic clunking or grinding noise while the engine is idling in neutral or park. If a bolt has broken or become loose, on the flexplate, these can misalign the flexplate and cause the side of the plate to come into contact with other components. If the flexplate becomes warped this can cause metal-to-metal contact with the cover, or the starter drive mechanism, and can also make a knocking noise once the vehicle is put in forward or reverse gear.

Bad vibrations – if, when driving the vehicle, you notice vibrations that may gain in severity as the speed increases then this can indicate a flexplate fault – sometimes pointing to a balancing weight that has become dislodged.

Other Flexplate Problem Causes

Flexplate malfunction can be caused in several ways, some of which require a well-equipped workshop in order to diagnose but some common ones are:

- The engine or torque convertor is out of balance.

- A fault on the starter drive sometimes causes teeth or the ring gear to wear rapidly or snap.

- The flexplate bolts have not been set for the correct torque settings and tightened in the specified sequence.

If your vehicle develops a flexplate problem you will probably require the services of a trained mechanic with suitable tools and equipment on order to rectify that problem. Replacing/repairing flexplates is generally not a job for an amateur.

Sources:

- Flexplate – What Does It Do ? – What Happens When It Fails – Danny’s Engine Portal

- What is a flex plate in Ann Arbor MI – Ron’s Garage