As motorsports technology continues to evolve, so does what it affects. Some of these take the form of better in-race reliability, improved fuel economy, enhanced grip, and faster lap times. However, possibly the biggest impact is safety.

As the all-inclusive spectrum of racing across all series—such as NHRA, Formula Drift, SCCA Club Racing, NASCAR, and even IndyCar—evolve, so must the measures put in place to keep its drivers as safe as possible. Especially when it comes to materials and components, ranging from fire-retardent clothing to transmission bell housings and shift boots. That's where the SFI Foundation comes into play.

The SFI Foundation has been around since 1978 and is a leading authority in developing safety standards for specialty and performance racing equipment, as its website proudly states. These friendly folks recently invited me to take a tour of their facilities and learn more about how they operate—let's discuss what SFI is, how it tests and develops safety specifications, as well as how it operates as a surprisingly lean operation.

Small Staff, Big Impact

Nestled in a nondescript office building north of San Diego, California, SFI's HQ is as easy to miss as a shooting star. Any passerby who didn't know the name might assume it's some kind of random real estate office.

With less than a dozen staff, SFI keeps its operations lean, avoids extravagant digs, and operates as a non-profit. Less overhead means less cost to pass on to parts and equipment manufacturers who produce products to their specifications. It makes the bulk of its funding by selling labels to these manufacturers to prove this, and there are many, many specs that are accepted by many, many sanctioning body members and affiliates.

The core of SFI exists in SoCal and is comprised of the main office and its testing facility just down the road. However, it also maintains a presence in Indianapolis and subcontracts some of its engineering work to a select group of firms that are equipped to perform extensive testing.

Thorough Above All Else

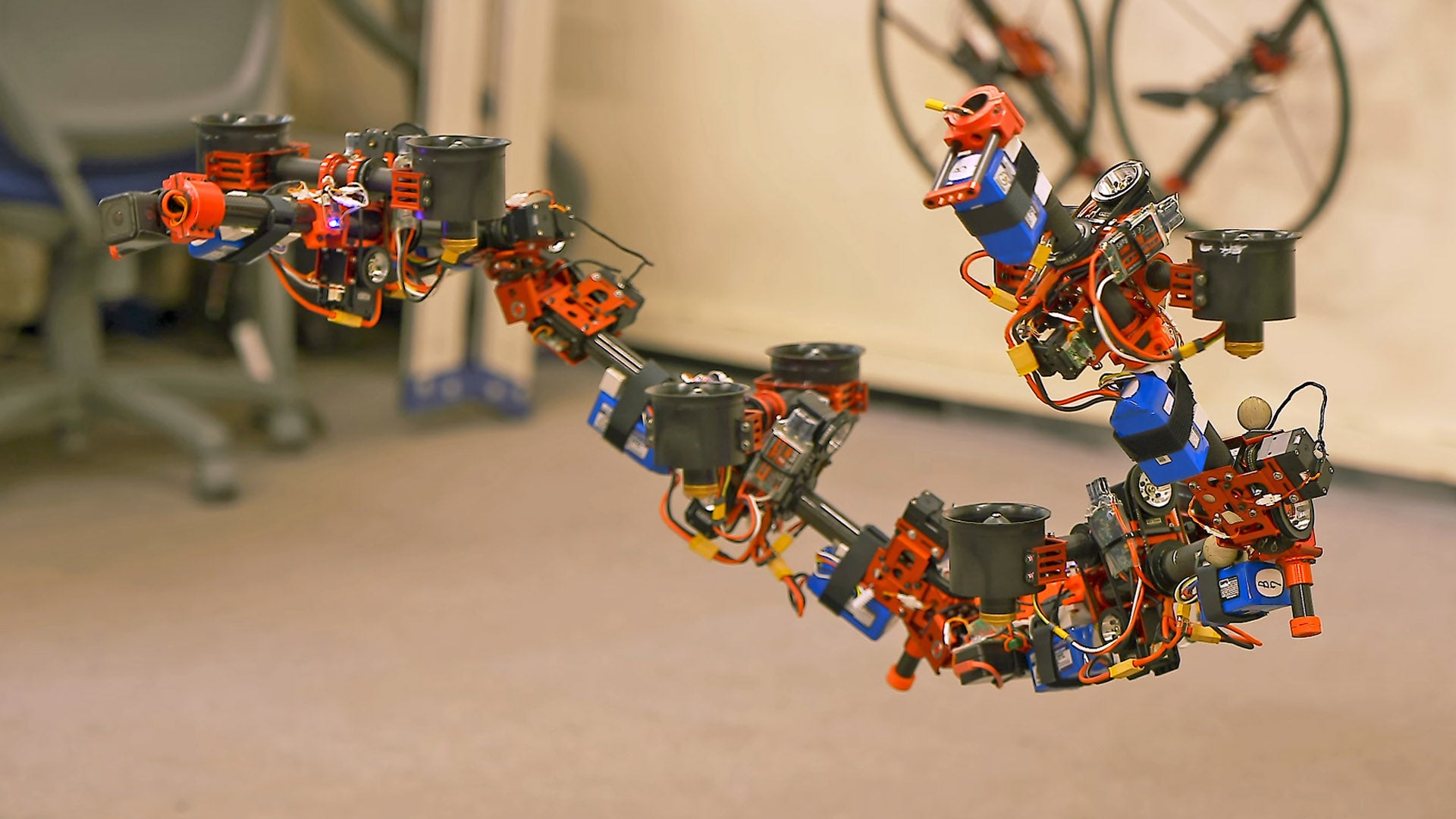

I was especially interested in hearing more about how SFI tests equipment to prove it meets its specs. The stuff it tests ranges from a fire-resistant balaclava, better known as a head sock, to other key pieces of the safety puzzle, like a window net, head and neck restraint (HNR), or six-point racing harness. HNR testing is primarily done in Indiana at the Center for Advanced Product Evaluation. SFI also tests mechanical parts like wheels, clutches, flywheels, supercharger restraints, and more.

To start, SFI tags are only good for two years from the product's manufacturing date. While the opposing viewpoint might be that this is simply a cash grab, the real reason is far from it. To ensure the highest level of integrity—safety equipment is routinely exposed to hot sun, hot in-car temperatures, high g-forces, racers' sweat, and more—this window ensures that racers will always be protected. "That two years is based on hard data," Mike Hurst, Technical Manager of SFI explained. "It's also, admittedly, worst-case scenario when it comes to things like belt webbing life." Then, if the product is damaged in any way, such as involved in a crash, burned by fire, and so on, it should be replaced immediately.

Hurst is a racer himself, as he's been infatuated with rally racing for most of his life. Not only was it great to chat with him about SFI, but to also hear all about his Cosworth-powered Ford Capri.

Oftentimes, products with just SFI tags affixed to them (many products are both FIA homologated and have SFI tags sewn on) are less expensive than FIA homologated products. "It's cheaper because we're more efficient—FIA homologation is more expensive than entering the SFI program and buying the labels from us," Hurst said.

Interestingly, some products' testing for safety doubles as an easy way for sanctioning bodies to write their rulebooks. Case in point: the required shifter boot in the previous-generation NASCAR Cup car had an SFI tag on it. This not only ensured protection from fire, but also disallowed teams from coming up with crafty methods to improve under-car aerodynamics.

What SFI Actually Does

The thing about SFI is, it isn't doesn't create the standards, but rather provides proof that products have met certain standards. It has over 100 specifications that are developed in cooperation between manufacturers, sanctioning bodies, and itself. "We don't just pick standards out of the air, sanctioning bodies make requests," Hurst clarified. "We get safety experts together, hold meetings, work with the sanctioning bodies, and then come out with the spec to provide to manufacturers."

And it's the sanctioning bodies—whether SCCA, NHRA, IMSA, NASCAR, or whoever—who look to SFI to realize ensuring all products will perform the same.

"Before SFI, there really were no standards on safety equipment, but there were manufacturers making, for example, seat belts for race cars," said Hurst. "But there were no standards on what kind of design and strength requirements—how strong did it have to be? They were just sewing up whatever they thought would work. Maybe more diligent manufacturers did their own research and design, but they all do better when you give them a goal."

And that goal is the specification. For example, based on instrumented crashes and simulations, x needs to be y strong.

What's more, giving them a standard to meet allows them to then come up with something that's perhaps more comfortable, lighter, easier to produce, or whatever their end goal might be. When you think about it, standards help inspire ingenuity and competition.

When a manufacturer buys an amount of SFI tags to affix to its products, that's telling the consumer and sanctioning body that its product meets a certain standard. Racers can take comfort in, and sanctioning body tech inspectors will confirm, that they'll be protected in the event of an impact, fire, or whatever potential nightmare scenario goes down on the track.

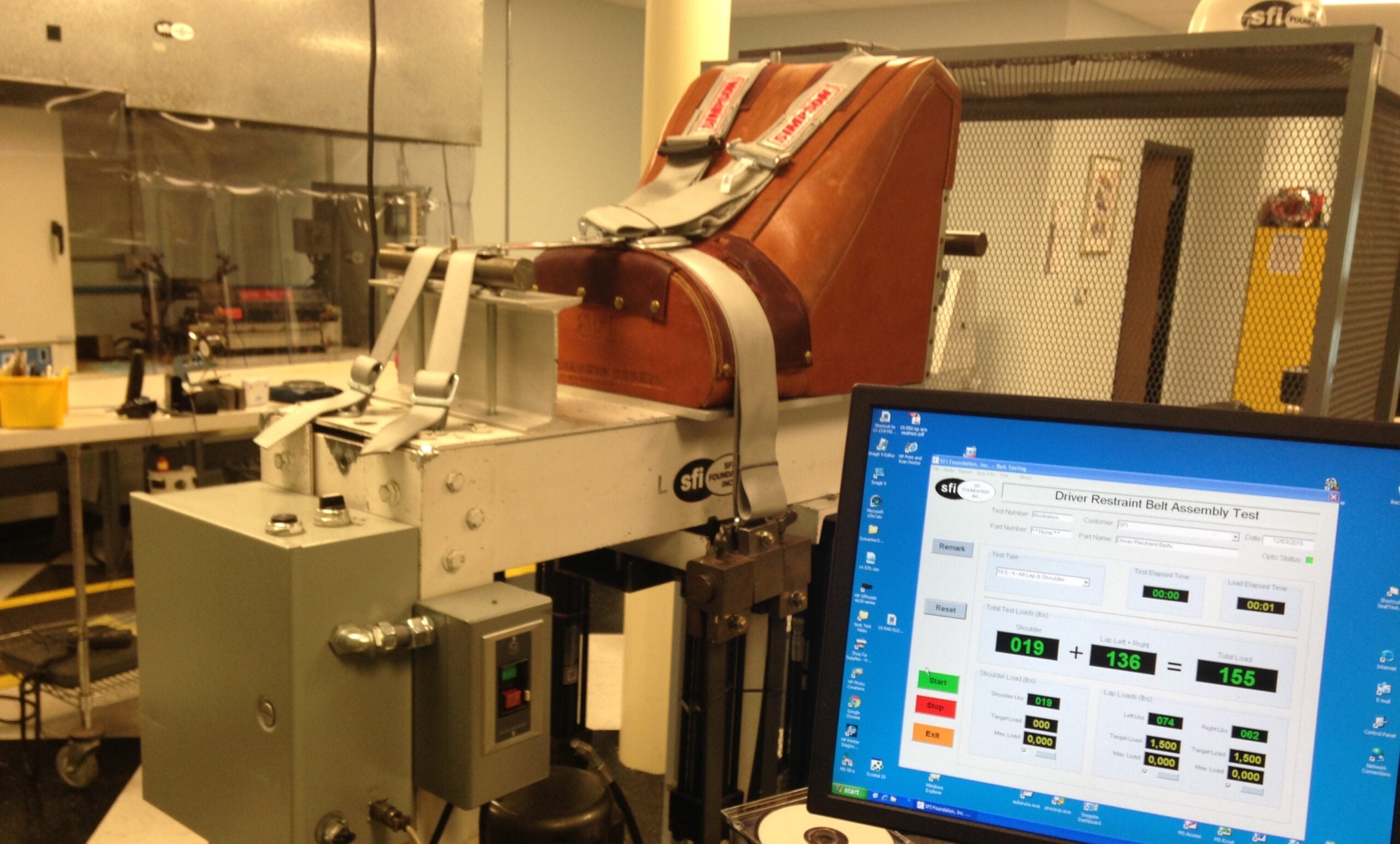

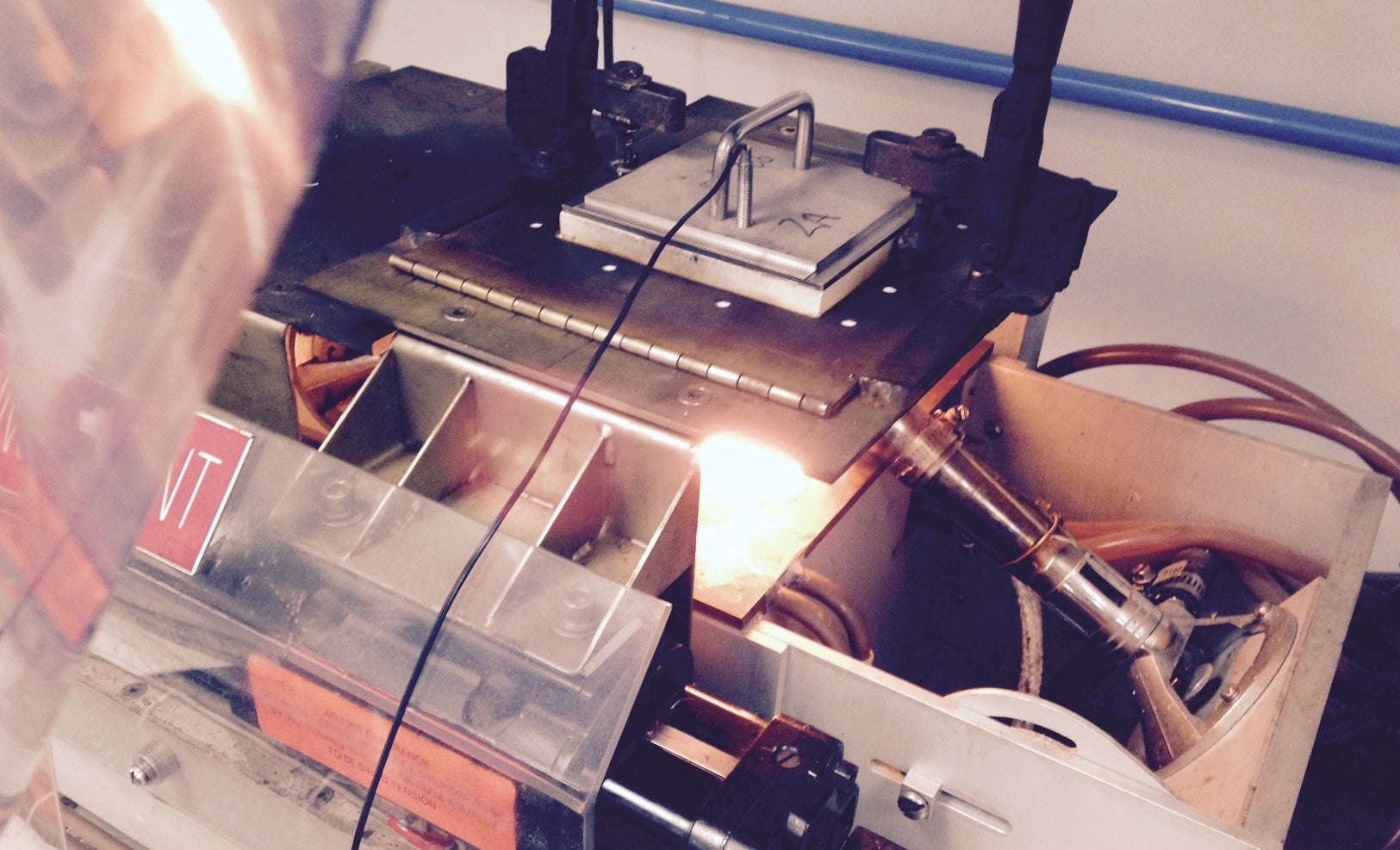

Testing harness belts (left) and testing an article of clothing's thermal protective performance (TPP)(right), Images by SFI

SFI's Testing

The bulk of SFI's testing goes down at yet another nondescript location in San Diego County, though instead of an office it's a complex testing laboratory.

Inside, there's a wide range of devices to thoroughly and scientifically test flame retardancy, impact resistance, stretch, resistance to weathering, and more. The employees who put products through the wringer have a wide range of tasks, from setting fire to fire suits to blowing up turbochargers. While some of the contraptions they use are seemingly simple in function, they are set up to record precision data and are often continually modified to keep up with the evolution of motorsports. In fact, Hurst mentioned that he was in the process of building a new testing device for his team's thorough instrumentation inventory.

Depending upon the product, it gets hit with forces similar to on-track crashes, pulled as hard as a head-on collision with a wall at high speed, exposed to fire, spun up to many thousands of rpm, or even put through the same environmental impact as UV exposure and major temperature changes. The latter happens in a controlled and accelerated fashion, which is a step up from the organization's previous method of mounting them to the roof of its previous test facility just a tad further north in the city of Escondido.

Additionally, not all tested products are submitted samples from companies. Part of SFI's quality assurance comes in the form of ongoing testing, such as purchasing SFI-tagged products from major retailers to ensure companies in their program aren't cheapening out on their production practices. Or, even if they aren't, if a company moves its production facilities, or even changes its supplier (especially in light of the recent worldwide materials shortages) SFI wants to make sure that safety doesn't suffer.

Further Testing and Beyond

A major issue in motorsports safety is counterfeit and misrepresented merchandise. One of the biggest offenders is cheap harnesses that often sport fake SFI tags, which are almost certainly severely lacking compared to the real thing.

One of SFI's jobs is to investigate these products and do everything it can to warn consumers. And by investigate, I mean technicians actually purchase and test them. SFI also sends out notices to sanctioning bodies informing them of what to look for, what the latest trends in counterfeiting are, and more. Thankfully, it keeps a list of approved products and manufacturers on its website for quick reference.

Various sanctioning bodies also look to SFI for assistance with tech inspector certification and training. For those unfamiliar, these are the folks who are inspecting gear and racecars to make sure they conform to the sanctioning bodies' safety requirements. Not only are inspectors educated on what to look for but sanctioning bodies are also reassured that these folks are qualified for the job. Folks with a background in engineering could be perfect for the job, but these standards ensure that they are.

There's a saying in motorsports that there's no such thing as too safe, at least there ought to be. While familiarizing one's self with specifications and expiration dates can be tricky and start to add up expense-wise, it's all in the name of protecting and preserving lives. The massive array of amateur and professional motorsports is a fascinating area of culture that draws passion from millions of people; the more we can do to ensure it stays that way, the better. The SFI Foundation's existence plays a major role in this.